PRODUCT

Masonry Stop Socks

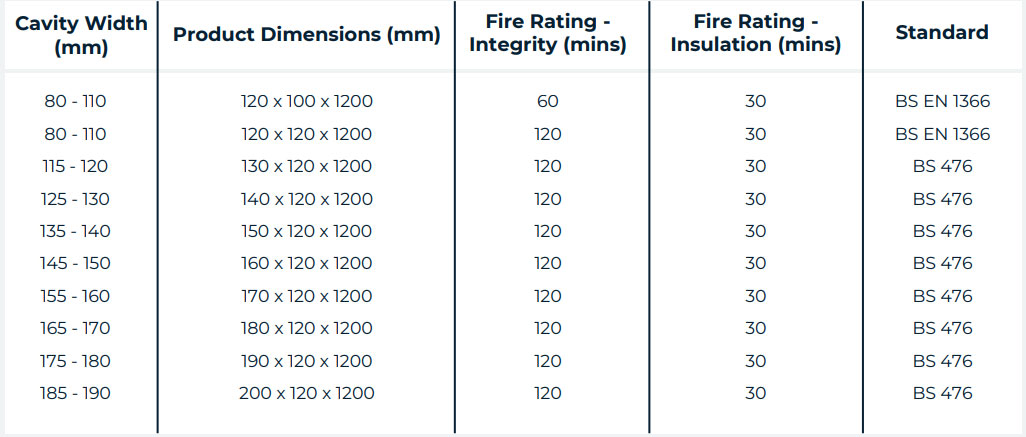

CCL Masonry Stop Sock consists of a length of flexible mineral wool slab fully enclosed in polythene.

Fixing

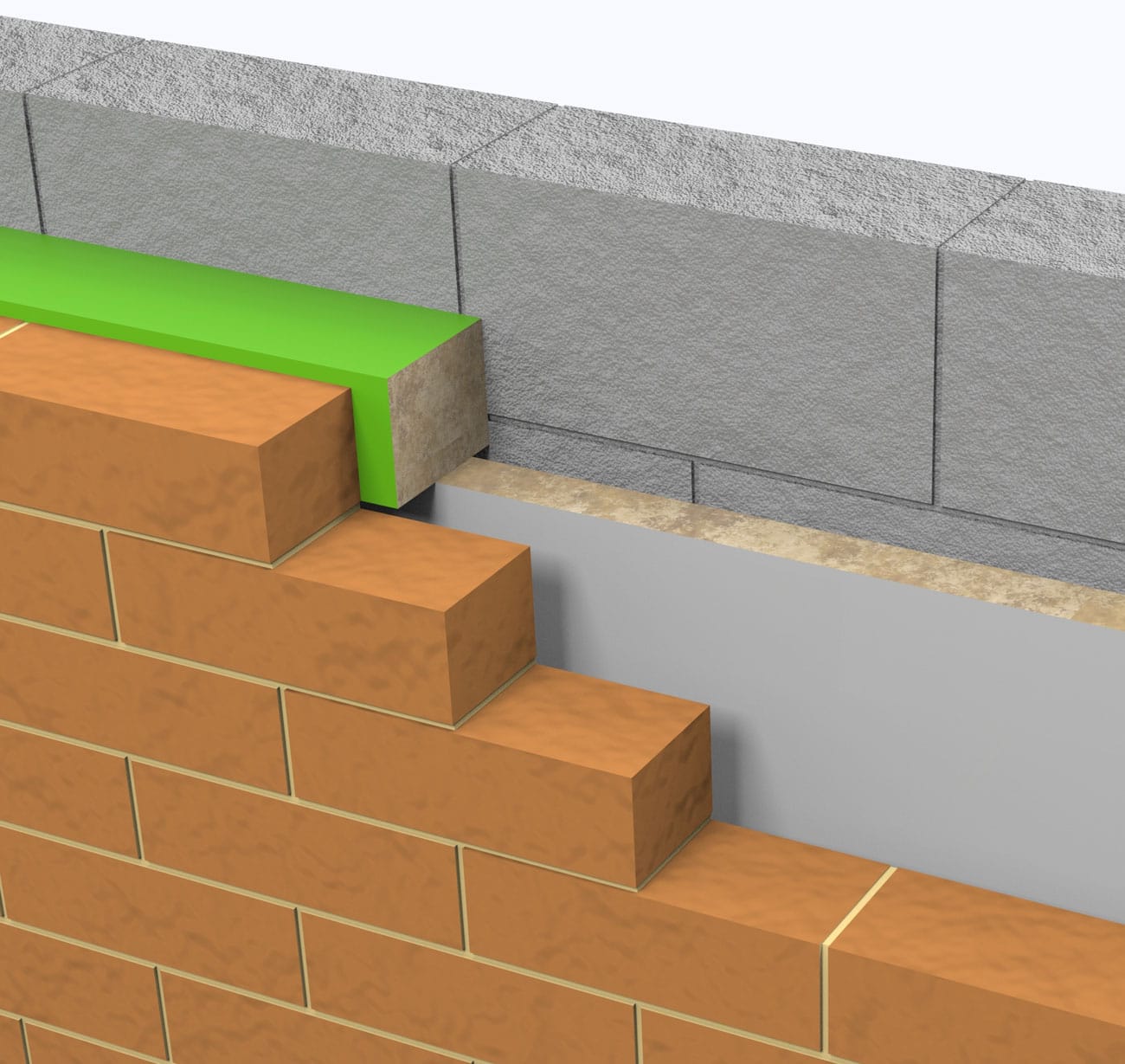

CCL Masonry Stop Socks are supplied 10mm to 15mm thicker than the cavity in which they are to be installed and are friction fitted during the brickwork process.

During vertical installation it is advisable to place a length of damp proof course between the cavity stop sock and the outer leaf.

During horizontal installation it is advisable to protect the Masonry Stop Sock with a damp proof course of cavity tray immediately above with a minimum 100mm upstand.

Special attention must be paid to the joints to ensure these are very closely butted. Cavity barriers may fail at the joints if a gap is left.

Packing Specification

All product data is managed by Concept Conversions Ltd.. Please see Terms of Use for CCL.