PRODUCT

Open State Cavity Barrier System

The CCL Open State Cavity Barrier System is designed to prevent the spread of fire and smoke in open state cavities where a continuous vented air layer is required within the facade design.

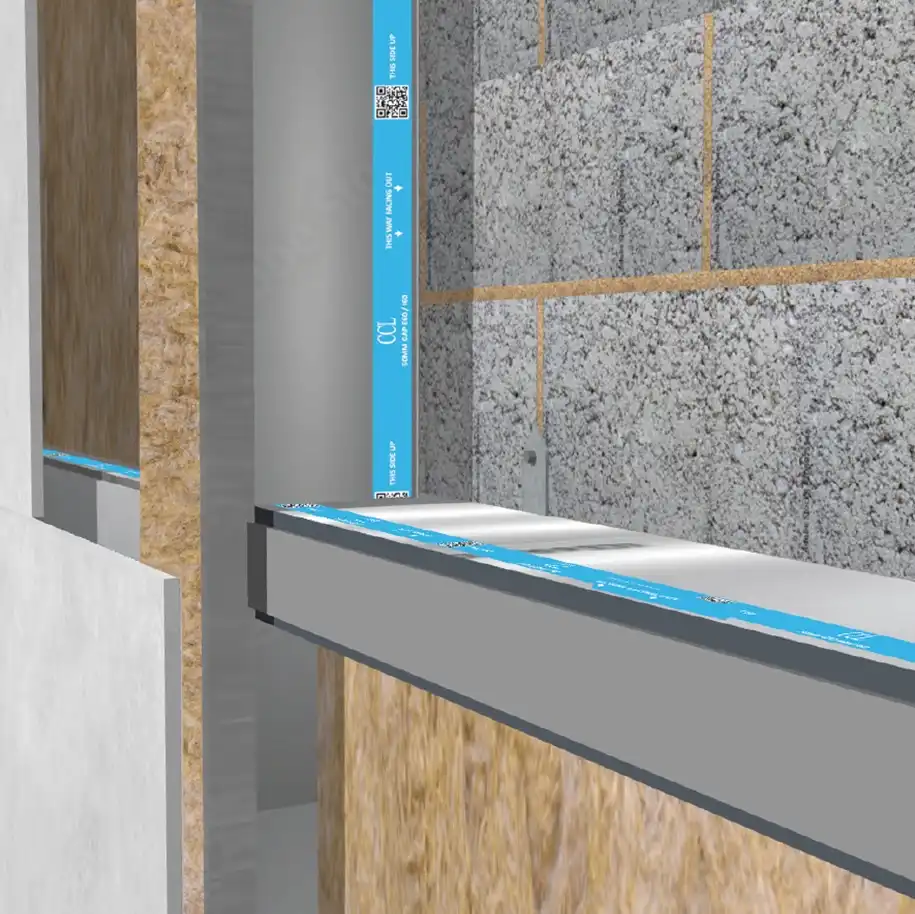

Installation – VRCB

The CCL VRCB is designed to be installed under compression across the cavity void at no less than 5mm and should be installed prior to the HRCB, in a continuous vertical layer, ensuring all of the joints are tightly butted and taped.

The CCL VRCB is secured to the inner substrate by either friction fitting or mechanically fixed using the foldable fixing brackets with an appropriate fixing for the substrate type.

For mechanical fixing, the foldable brackets are folded/bent to the required size and secured to the substrate. The VRCB is pushed onto the bracket at the mid point ensuring the barrier is penetrated by the bracket to a minimum of 60% and is secured firmly against the inner structure.

For friction fitting, The VRCB should be installed as the substrate and the facade is progressed, ensuring the barriers are installed under compression as detailed above.

Should any small gaps (<5mm) be present due to substrate tolerances, they should be filled using intumescent mastic.

All joints should be sealed with CCL foil tape before installation of the CCL VRCB commences.

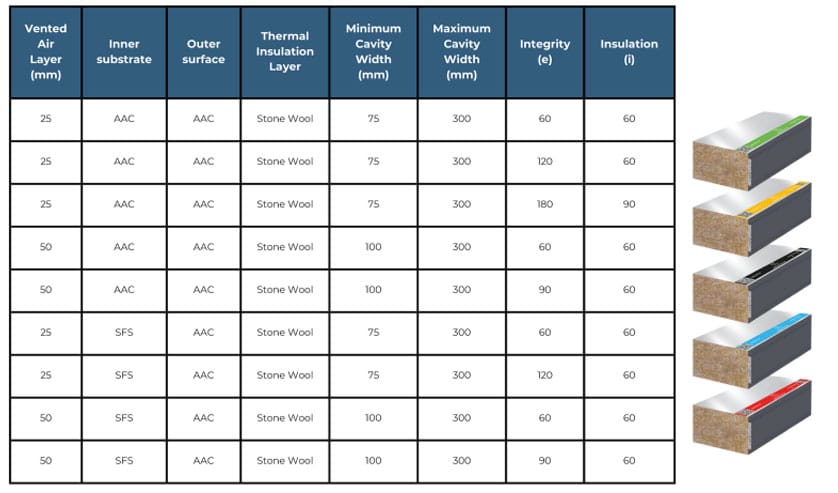

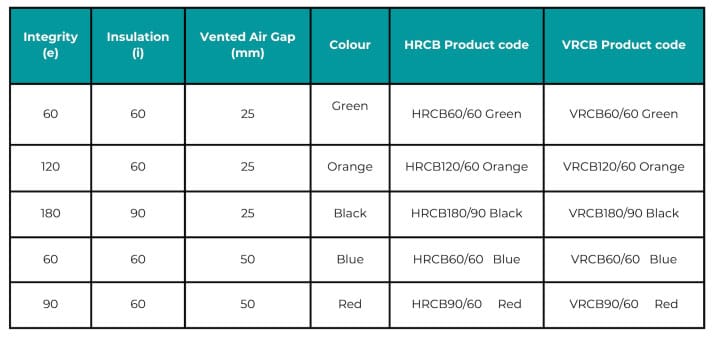

Product Identification

Prior to installation, the CCL VRCB should be checked to ensure the performance matches the project requirement.

This can be carried out quickly onsite by checking the colour of the strip applied to the surface of the barrier, which details the fire performance.

For mechanical fixing, the foldable brackets are folded/ bent to the required size and secured to the substrate. The VRCB is pushed onto the bracket at the mid point ensuring the barrier is penetrated by the bracket to a minimum of 60% and is secured firmly against the inner structure.

Installation – HRCB

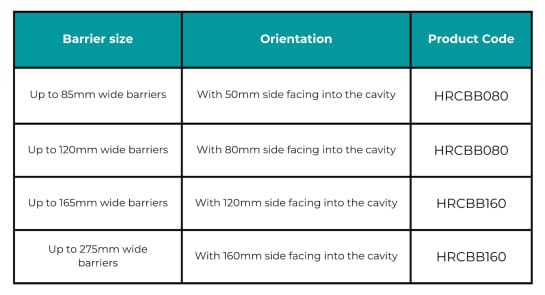

The CCL HRCB range should be mounted on brackets to the inner structural surface, using the CCL multi bracket at a minimum of two per linear metre, or at a maximum of 500mm centres.

The CCL Multi bracket is secured to the inner surface using appropriate fixing for the substrate.

The cavity barrier is then pushed onto the bracket at the mid depth (thickness) point, with the intumescent layer facing into the open cavity/airspace.

Ensure the barrier is penetrated with the multi bracket to a minimum of 60% and is secured firmly against the inner structure, aiming for zero gaps between the barrier and the substrate.

Should any small gaps (<5mm) be present, due to substrate tolerances, they should be filled using intumescent mastic.

All joints with subsequent lengths of barrier, or at junctions with support rails and vertical barriers, must be tightly butt-jointed ensuring there are no gaps.

The upper joint should be sealed with CCL foil tape, taking care not to apply tape over the intumescent layer.

Once installation is complete the CCL HRCB should be checked to ensure there are no gaps, that the joints are sealed as above, and that the intumescent layer is free from restrictions or obstructions which may prevent it from expanding.

Product Identification

Prior to installation, the CCL HRCB should be checked to ensure the performance matches the project requirements.

This can be carried out quickly onsite by checking the colour of the strip on the upper surface of the barrier, which details the fire performance as well as the air gap as shown opposite.

Additionally, the CCL HRCB contains information showing the correct orientation for the barrier to be installed, along with the QR code linking to the BSI. Identify database, where MSDS, full installation instructions and other useful information are available for download as required.

Disclaimer

It is the responsibility of the customer to make the final choice when selecting products for use in construction projects. CCL provide data in good faith, however the information provided is not a recommendation and decisions are not carried out by CCL. Where relevant, CCL products should be installed in-line with test certification and in build-ups that match the specific test. In presenting any technical information we cannot claim to serve in any but an advisory capacity and can undertake no liability since the actual conditions and circumstance of use are beyond our control.

All product data is managed by Concept Conversions Ltd.. Please see Terms of Use for CCL.