Description

CCL Raised Access Floor Firestop Slab consists of rigid slabs of dense mineral wool faced on both sides with reinforced aluminium foil. The foil facing is printed with lines along the length to aid the fabrication of cut panels on site.

Purpose

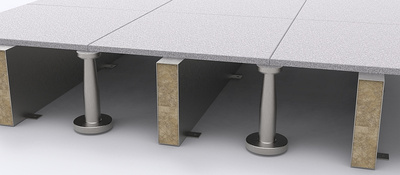

CCL Raised Access Floor Firestop Slab is designed to prevent the passage of fire and smoke through the void formed under raised access floors. They are installed where a fire barrier requirement is created by either the need to subdivide large uninterrupted cavities or aligned under a partition to maintain the partition’s fire rating.

Benefits

- Available in slabs or cut to size

- Suitable for cavities up to 600mm

- Simple to cut and install

- Takes up building tolerances

- Excellent acoustic properties

Dimensions

RAF Slab 60 – 75mm x 600mm x 1200mm

RAF Slab 120 – 100mm x 600mm x 1200mm

Standards and Performance

The mineral wool core of a CCL Raised Access Floor Firestop Slab achieves a fire classification of Euroclass A1 as defined in BS EN 13501 -1.

CCL Raised Access Floor Firestop will exceed the requirement to provide a 30 minute cavity barrier as defined in Approved Document B of the Building Regulations 2010 (2019 edition).

CCL Raised Access Floor Firestop 60 provides 1 hour fire resistance unsupported in voids up to 400mm (over 400mm requires support with fixings).

CCL Raised Access Floor Firestop 120 provides 2 hours fire resistance unsupported in voids up to 400mm (over 400mm requires support with fixings).

Fixing

Prior to fixing the void height should be measured to which 5mm should be added to allow for compression fitting of the barrier. The slabs may be ordered factory cut to suit most voids if the cavity dimensions are already

known. Supply in slab form may be of benefit if the void dimension is unknown or where it may vary, the standard product is supplied in slabs measuring 600mm x 1200mm and are easily cut on site using a sharp

serrated knife.

The cut slabs are compression fitted between the structural floor and the raised access floor ensuring that all joints are tightly pushed together. The joints should be sealed using Class 0 rated aluminium foil tape to complete the smoke seal. Where required , the fixing brackets are impaled centrally into the base of the slab on either side at approx. 600mm centres and are mechanically fixed to the structural floor using suitable metal fasteners.

The brackets are supplied flat with a series of notches and fixing holes that enable them to be easily fabricated by hand to suit the barrier height required. The bracket should penetrate the barrier by more than half of the void being filled.