Description

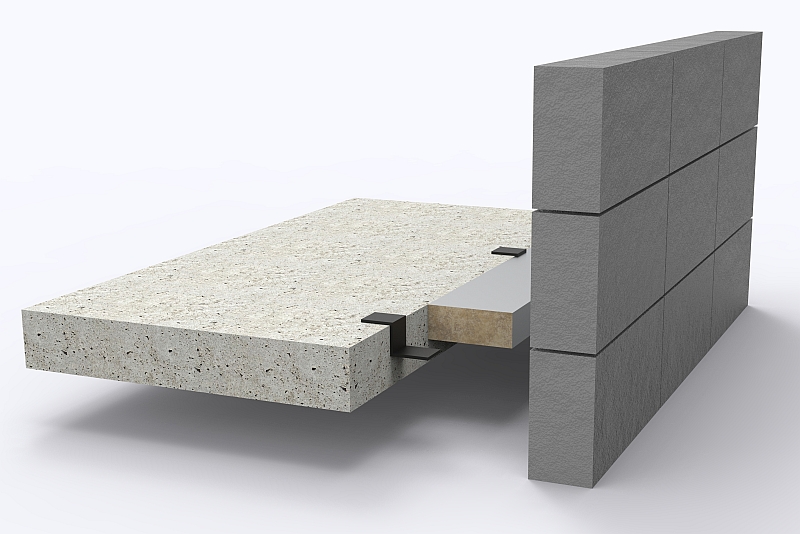

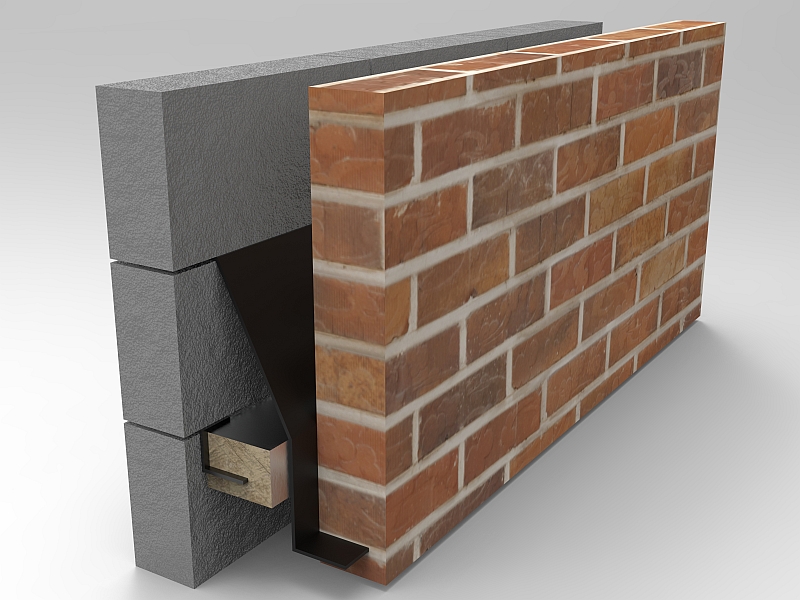

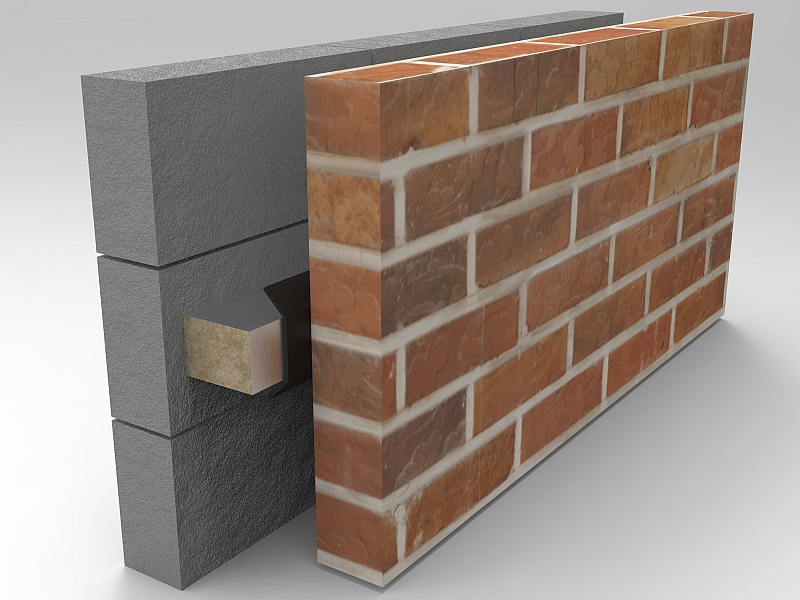

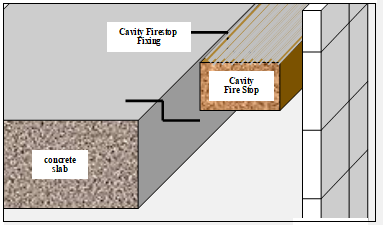

The CCL Cavity Fire Stop Slab (CFSS) is a fire resistant barrier designed to prevent the spread of fire and smoke in closed state, non vented cavity constructions.

The CCL CFSS range is designed for use vertically and horizontally in closed state, non-vented cavities from 50mm to 300mm.

Manufactured from high density, non-combustible rock mineral wool, faced on both sides with reinforced aluminium foil, the barriers are installed either friction, or mechanically fixed under 5mm compression.

Suitable for use on slab edge, masonry and SFS wall types, the CCL CFSS range is available in slab form in two sizes, either, 1200mm x 1000mm or 600mm x 1000mm, foil faced both sides with one face printed with cutting guides to facilitate on site fabrication.

The CCL CFSS range is also available in factory produced sizes to suit the required cavity width reducing installation time as well construction site waste.

The CCL CFSS range has been tested in accordance with EN 1366-4, 2021

Standards and Performance

The mineral wool used in the production of Concept Cavity Firestop Slab achieves a fire classification of Euroclass A1 as defined in BS EN 13501-1.

The CCL CFSS range achieves fire resistance performance of up to 240 minutes integrity and insulation on masonry and 240 minutes integrity and 60 minutes insulation on SFS substrates* when used in cavities between 50mm and 300mm.

The CCL CFSS range has been tested in accordance with EN 1366-4, 2021

Dimensions

Cavity Fire Stop Slab 60/60 600mm x 1000mm

Cavity Fire Stop Slab 60/60 1200mm x 1000mm

Cavity Fire Stop Slab 120/60 600mm x 1000mm

Cavity Fire Stop Slab 120/60 1200mm x 1000mm

Factory produced sizes from 55mm to 305mm in 1mm increments to specified sizes.

Fixing

The CCL CFSS is installed under compression utilising the CCL Fire Stop Clips (FSCLIP).

When installed vertically and providing the barrier is supported at the base and the internal and external surfaces are completed as the barrier is installed, the CCL FSCLIP may be omitted.

The CCL FSCLIP should be bent into a Z shape and penetrate the firestop by a minimum of 60% of its overall width at a rate of 2 per length (approx. 300mm from end to end).

Lengths of the CFSS should be tightly abutted to each other and there should be no gaps present between the barrier and the substrate.

The barrier should be securely fitted into the cavity ensuring it is compressed by approximately 5mm and the ends form a tight butt joint.

The fixing clip should then be mechanically fixed to the floor slab or inner leaf.

All joints should be sealed using 100mm CCL Foil Tape.